Radiant heating under wood flooring

A winter is coming and it will be long and cold… We must think how we can make it comfortable and warm, while we are starting one of the systems we have already installed in our premises. The discussions about the best, the cleanest, the healthiest and the most economic system are usually in wane and the opinions vary. This text will look upon the radiant heating, or to be more precise, parquets above the underfloor heating.

Because of hygroscopic characteristic of wood and because of its dimensional instability, as well as due to changes in relative air humidity and temperature, an opinion has appeared that installing parquets above the system of hot water heating is very risky. There is also a possibility of drying of the wood and appearance of cracks. But is this really true? Several decades of practice and good experience, as well as detailed researches on this topic tell something completely different. Of course, only under condition that all technical requirements for installing and starting the system are fulfilled and proper parquets are chosen.

Heated wood floors

The forerunner of underfloor heating, hypocaustic heating, was known in the ancient Rome, according to the testimony of Vitruvius in his famous work “On Architecture”. Material evidence is present throughout Europe. Hypocaust system used a simple furnace in which wood or charcoal has been fired. It was placed under the floor and it did not have a chimney, but the smoke has been led away through a special closed system through the walls and floors which were lifted on low stairs. After a longer period of firing, the stairs and the floor would be heated and then the firing would be stopped.

The heated channels would be filled with fresh air from the outside which would be heated and let into the rooms through special gaps. This system was spread and had different applications – different rooms were heated and especially famous Roman bathrooms. Unfortunately, with the collapse of the Roman Empire, this system has disappeared, while the bathrooms were rare in Europe during the following centuries. So as the culture of body hygiene. (The tradition has been continued with the famous Turkish bathrooms – hammams.)

However, in the 1970s, the radiant heating has been developing again and it comes to us in the form we know today. Its key advantage is in the fact that large heated surface needs low working temperature with which energy efficiency is achieved, and the heat distribution is balanced when compared to the classic central heating. And, from the aesthetic point of view, it does not affect the appearance of the interior and it clears the walls next to the windows, which are usually reserved for radiators or other heaters.

Then the walls are free for furniture, or large glass panels can be placed.

The biggest objections to under floor heating are the higher possibility of dust and appearance of allergies, as well as specific inertia of legs which appears because of the heat inversion (human body is accustomed to the situation where the upper part of the body is warmer, while the radiant heating gives a reverse case).

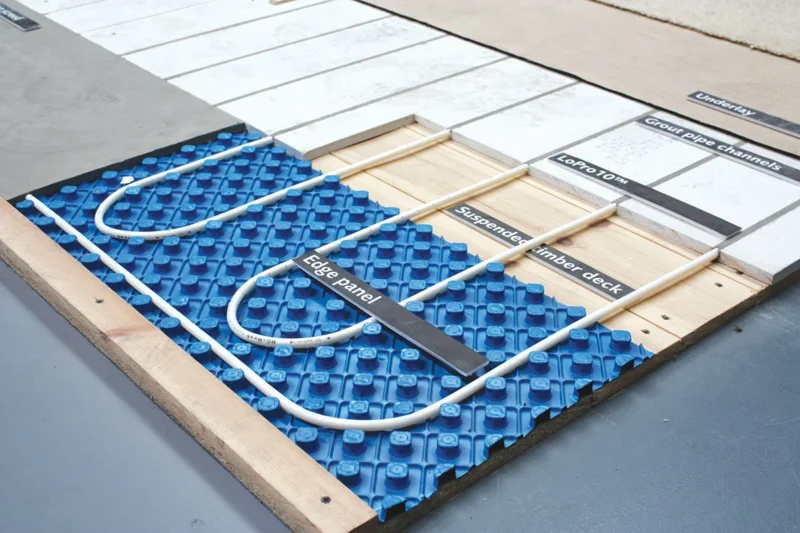

Radiant or underfloor heating system

Ceramic tiles or different types of stone have been placed on the underfloor heating, but the practice has shown that wooden flooring, or multilayered parquets can be placed on the floors with hot water under floor heating.

Because of their specific construction, the best are two-layered parquets whose thickness is less thin (it goes from 9 to 13mm), in order to lessen the heat resistance and heighten the heat conductance.

Also, three-layered parquets can be used whose stability is exceptional. Massive parquets are not recommended for placing on underfloor heating because there is a risk of deformation. Oak and darker wood species, as well as thick wood and thermally treated wood have been a good choice. On the other hand, beech, cherry, ash, Canadian maple, jatoba and according to some researches, all types of wood which grow on the Southern hemisphere should be avoided.

Specific schemes, such as “fishbone” or placing in the shape of a square, heighten the stability of the wood and lessen the possibility of gaps between the pieces, in relation to the parallel piece. Selection of wood also affects stability of the under floor heating. Parquets with quieter, radial texture (so called “frizz”) are recommended in comparison to those with tangential texture (“flader”) because the strangulation of wood is half less.

When it comes to final, surface machining, the advantage is rather given to oiled and waxed surfaces than to the lacquered ones, because of the possibility of sticking along the side bonds.

It is important to pay attention to the fact that the temperature measured on the surface of the parquets should not be over 25°C and the relative air humidity should be kept between 50 and 65% (over 60% is recommended) in order to avoid the appearance of gaps and cracks. During the placing it is important to glue the hardwood along the entire surface on the foundation using permanently elastic adhesives which are not made as water-based.

Hardwood on the underfloor heating should not be covered with carpets or rugs because under them a higher surface temperature is developed than with open floor which causes faster drying of the wood and appearance of bigger cracks.